DIFFUSION BONDING

Diffusion bonding is a process by which atoms migrate across particle boundaries, leading to neck formation between particles. This gradual movement of atoms enables the bonding of adjacent powder particles, resulting in reduced porosity, increased density, and improved mechanical properties. The process is highly sensitive to temperature, time, and atmosphere, requiring careful control of each parameter to achieve desired properties.

ATMOSPHERE CONTROL

Atmosphere control is critical to the sintering process to prevent oxidation or contamination of the metal. Sintering can occur in various atmospheres, such as vacuum or inert gases, depending on the material and end-use requirements. Certain properties of materials such as strength and corrosion resistance in stainless steel can be tailored to fit a given application though proper control in sintering atmospheres. In soft magnetic materials, atmosphere plays a critical role in magnetic performance.

Other sintering parameters such as temperature, time, and cooling rate must also be tightly controlled depending on the specific metal being processed and the intended properties of the final product.

HARDENING

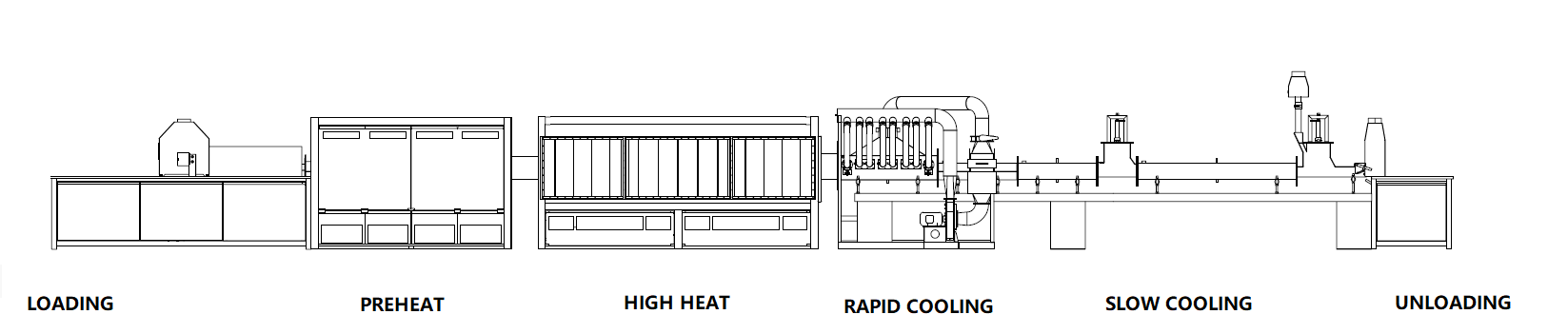

Sinter hardening is a specialized process used to enhance the mechanical properties of ferrous components during sintering, without a secondary heat treatment operation. By subjecting the components to a rapid cooling rate from the sintering temperature, martensitic microstructures can be achieved allowing for increased hardness, strength, and wear resistance.

In addition to our belt furnace capability, FMS also has two high temperature vacuum furnaces with temperature capability up to 2400°F (1310°C), and gas pressure quench capability up to 5 Bar. Vacuum processing is crucial for achieving superior properties in stainless, soft magnetic, and high strength chromium-containing materials.