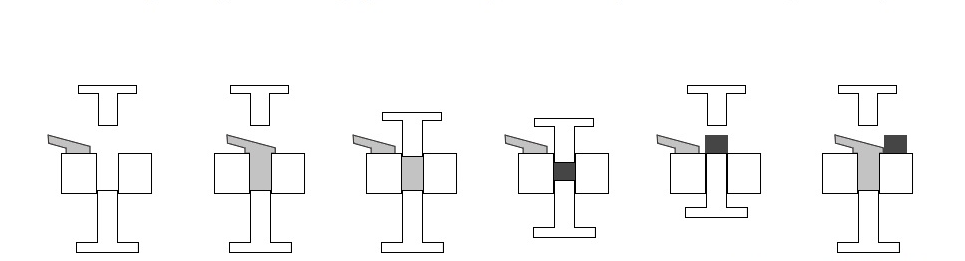

FILLING

The process begins by placing highly engineered metal powders of a specific shape and particle size distribution into a die cavity, which can have various configurations based on the intended final product shape. Once filled, a controlled amount of pressure is applied axially to the powder using upper and lower tooling members called punches.

COMPACTION

Under the influence of this pressure, the metal particles are rearranged, creating mechanical bonds through a combination of plastic deformation and friction. This results in the formation of a "green" compact with a consistent and dense structure.

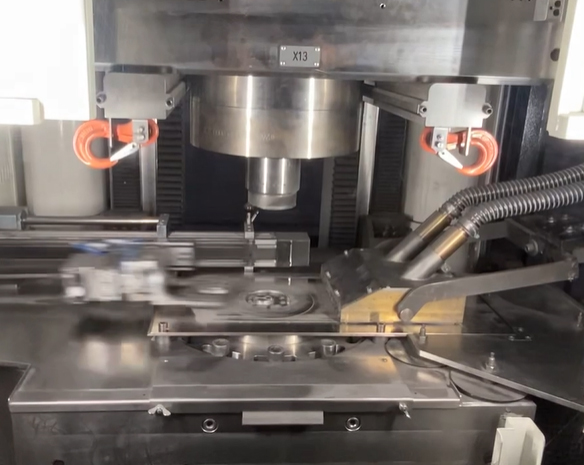

EJECTION & HANDLING

At this stage, the interparticle bonds are strong enough to allow for the part to be carefully handled but most green compacts can be broken either by hand or by being dropped onto a hard surface. A green part will not have any functional strength until after it has undergone the sintering process.