Whether your part is basic or a complex plated and machined assembly, the FMS team of experts will work to meet your unique production needs.

Soft Magnetic: Insulated particle, Phosphorous Iron

Ferrous: Low Alloy Steel, Nickel Steel, Copper Steel, Sinter Hardening grades

Corrosion Resistant: Stainless Steels 304, 316 and 410 alloys

Nonferrous: Brass, Bronze, Copper and Nickel Silver

Compaction Presses

Press Range: 2-1100 Tons (1.8-1000 metric tons)

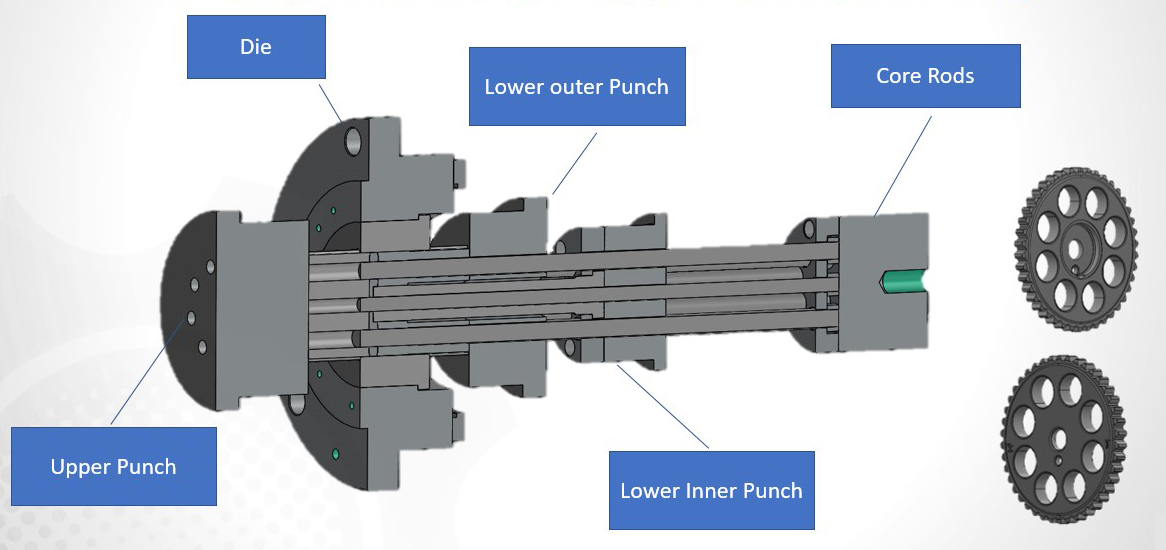

Multi-levels: Up to Seven Levels

Max. P/M Part Length: 5 inches (127 mm)

Automatic Sizing

Copper Infiltration

Sinter Hardening

High Temperature Sintering

Vacuum Sintering to 2400°F (1315°C)

Sinter Bonding

CNC turning and milling, conventional and wire EDM, drilling, tapping, reaming, boring, grinding, honing, oil and resin impregnation, roller burnishing, vibratory finishing, subassemblies, sizing, vacuum annealing, stream treatment, tumbling, deburring, hard turning, plating and assembly operations.

FMS provides extensive full-service CNC machining.

In today's business market, many companies find themselves on a compressed time-to-market schedule for new products.

For companies wishing to shorten lead times for final manufacturing of established, high-volume products, FMS's prototyping can expedite production of specialized tooling to meet your scheduling demands.

The FMS product development team of certified powder metal technologists meets weekly to evaluate new components and compatibility with the P/M process. This team of eight highly specialized, multi-disciplinary engineers and technicians provide our customers with an unparalleled level of research, design and engineering expertise.

We design and build our tooling in-house to provide the highest quality and fastest delivery.

Resonant Acoustic Method NDT (RAM NDT™) inspection system, Zeiss DCC Coordinate Measuring Machine, DataMyte SPC data collection and analysis, carbon analysis, Rockwell and Vickers (micro) hardness testing, compression/tension dynamometer, gear analysis, soft magnetic performance analysis, metallographic examination.